18

2024

-

12

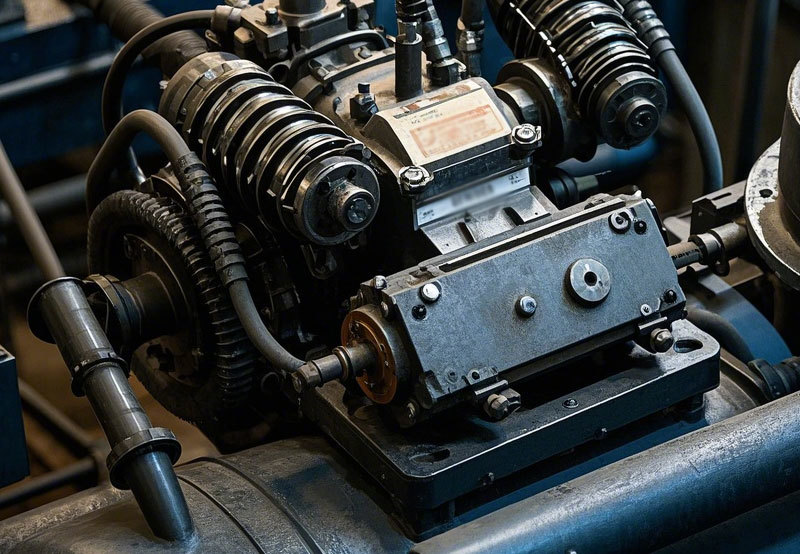

What components of the air compressor need regular maintenance?

Regular maintenance of air compressors is crucial for ensuring their normal operation and extending their lifespan. Here are some key components that require regular maintenance:

Regular maintenance of the air compressor is crucial for ensuring its normal operation and extending its lifespan. Here are some key components that require regular maintenance:

Air FilterIt needs to be cleaned or replaced regularly to prevent dust and impurities from entering the air compressor, affecting performance and lifespan.

Oil FilterThe oil filter should be replaced regularly to prevent dust and impurities from entering the machine, ensuring the cleanliness of the lubricating oil.

Lubricating OilIt needs to be replaced regularly to maintain lubrication and smooth operation of the compressor pump. The replacement interval depends on the type of compressor and usage, which may range from 500 to 2000 hours.

Oil-Gas SeparatorIt must be replaced when due or when the pressure difference exceeds a certain value to avoid motor overload and damage to the oil-gas separator.

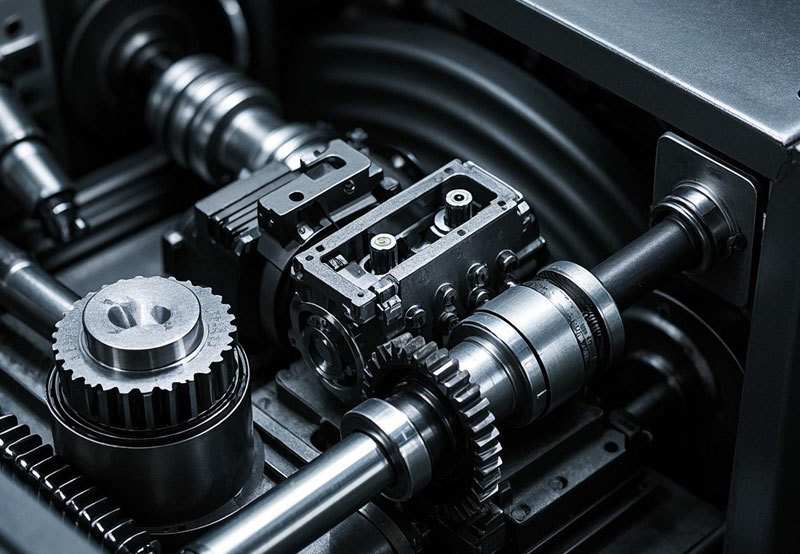

BeltFor belt-driven air compressors, the tension of the belt should be checked regularly and replaced if necessary to ensure transmission efficiency.

CoolerRegularly clean the heat exchanger to maintain optimal performance and prevent overheating.

ValveCheck and replace worn valves to maintain optimal performance.

FastenersRegularly check and tighten all fasteners, including bolts, nuts, and screws, to prevent leaks and ensure optimal performance.

MotorThe motor needs to be regularly lubricated or maintained according to the motor's user manual.

Intake ValveCheck the operation of the intake valve and its moving parts, and apply grease.

Minimum Pressure ValveCheck the opening pressure to ensure it is functioning properly.

Safety ValveCheck the responsiveness to ensure the safety valve can release pressure in a timely manner when the pressure is too high.

Drain ValveRegularly drain moisture and dirt to maintain oil quality.

Drive BeltAdjust or replace according to the degree of wear.

Cooling SystemRegularly check the cooling system to ensure it is operating normally.

Drainage SystemRegularly clean the drainage system to prevent water accumulation from damaging the equipment.

Electrical SystemRegularly check the electrical system to ensure it is operating normally.

Please note that the specific maintenance cycle and component replacement times should be determined based on the actual operating conditions of the equipment and the manufacturer's recommendations. It is also recommended to regularly inspect and maintain the equipment to ensure the normal operation of the air compressor and extend its lifespan.

Previous Page