01

2024

-

11

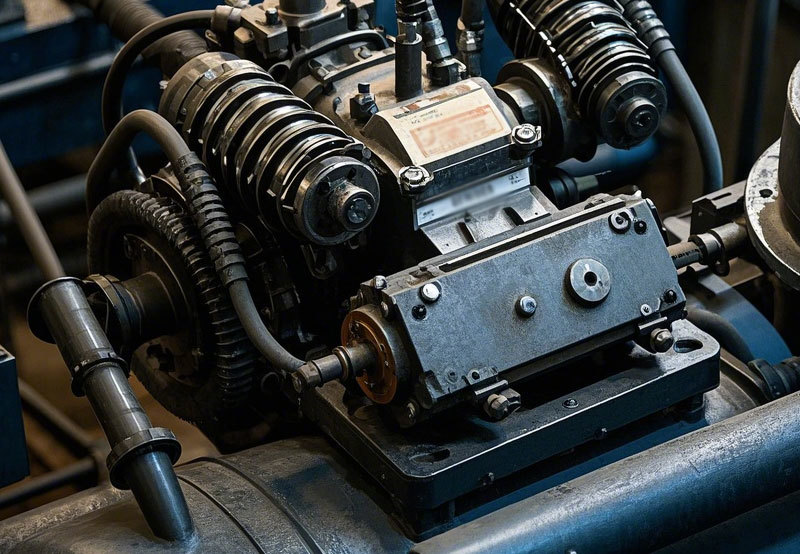

Reasons for Slow Air Output in Direct-Connected Air Compressors and Solutions

1. Aging of the oil seal: In direct-drive air compressors, lubricating oil is required. After the oil seal ages, the lubricating oil will leak out from the oil seal, causing the air compressor to have slow air output.

1. Problem Description

Directly coupled air compressors are a common type of compressor, widely used in industries such as manufacturing. However, during use, some users may encounter a problem: the air compressor is slow to fill with air, affecting its normal operation. So, what causes this problem and how can it be resolved?

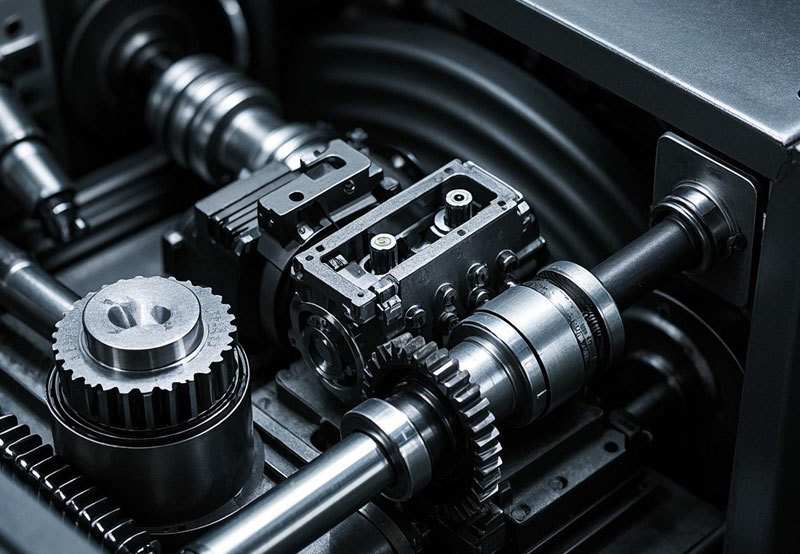

2. Cause Analysis

1. Aging of oil seals: Directly coupled air compressors require lubricating oil, and when the oil seals age, the lubricating oil will leak from the seals, causing the air compressor to fill slowly.

2. Damage to the intake valve: If there is a problem with the compressor's intake valve, such as internal damage to the valve or damage to the valve spring, it will lead to poor airflow into the compressor and slow filling.

3. Damage to the pressure regulator: The pressure regulator is an important component in the compressor that regulates air pressure. If the pressure regulator is damaged, it will lead to unstable air pressure and slow filling.

3. Solutions

1. Replace the oil seal: When the oil seal is found to be aging, it needs to be replaced promptly to prevent lubricating oil from leaking and causing slow filling.

2. Replace the intake valve: When a problem is found with the intake valve, it needs to be replaced promptly to ensure smooth airflow into the compressor and avoid slow filling.

3. Replace the pressure regulator: If the pressure regulator is damaged, it needs to be replaced with a new one promptly to ensure stable air pressure in the compressor and avoid slow filling.

In addition, users can pay attention to the following points during the use of the air compressor to avoid slow filling:

1. Regular maintenance: Regular cleaning, inspection, and lubrication of the air compressor can reduce the probability of faults.

2. Control usage: Reasonably control the usage of the air compressor and avoid overuse to effectively extend the compressor's lifespan.

3. Pay attention to the operating environment: During the use of the air compressor, attention should be paid to factors such as environmental temperature and humidity to avoid affecting the normal operation of the equipment.

4. Conclusion

This article analyzes the problem of slow filling in directly coupled air compressors from aspects such as aging of oil seals, damage to intake valves, and damage to pressure regulators, and proposes corresponding solutions. In daily use, users need to pay attention to the maintenance of the equipment and the operating environment to avoid faults and improve the efficiency of the equipment.