Product Series

A large-scale industry and trade integration enterprise specializing in the production and export of various pulse, oil-free, dental, vacuum, belt, direct connection, screw air compressors and their parts

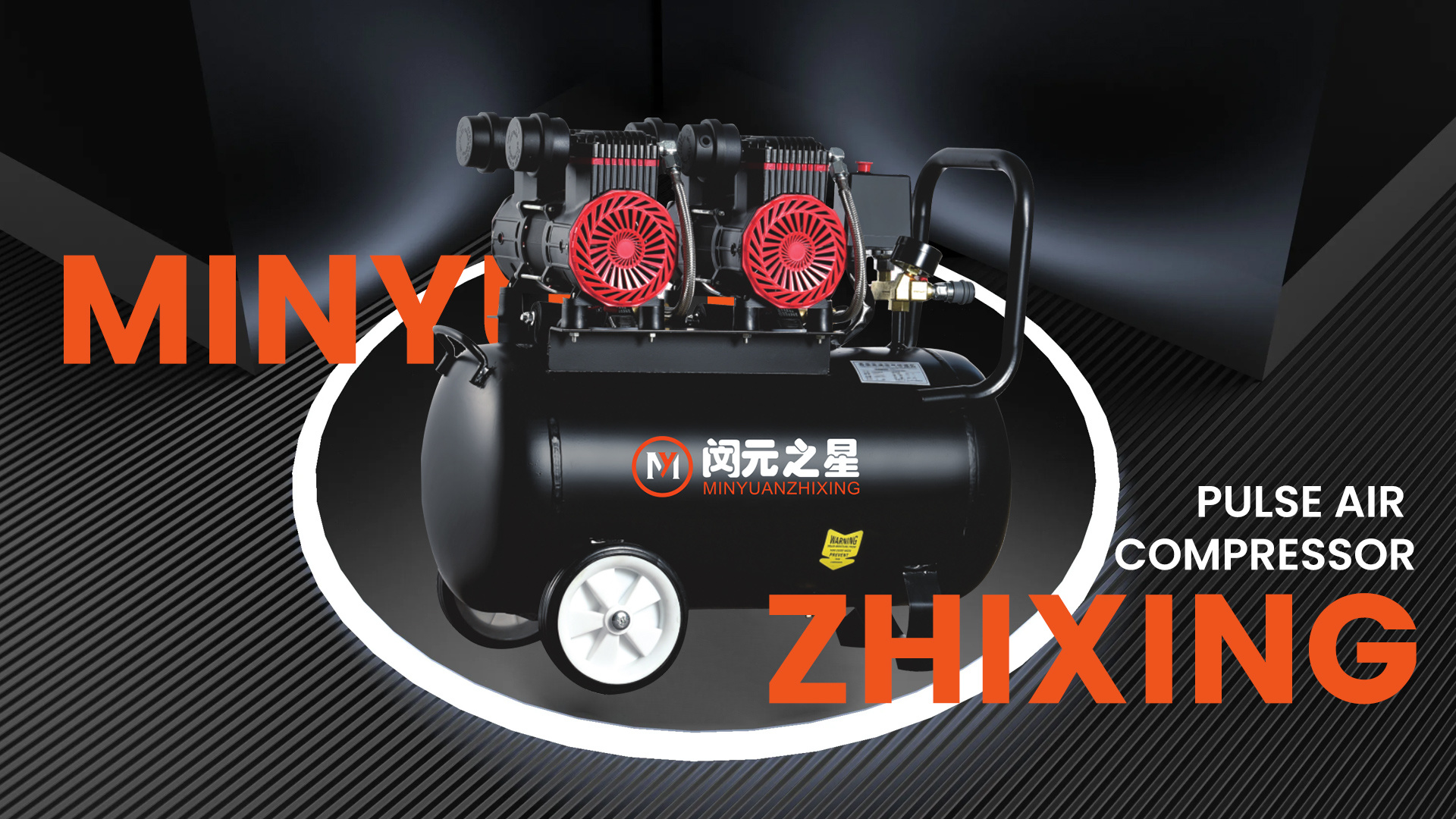

Pulse Air Compressor

The pulse air compressor is a device that uses compressed air to generate pulse pressure to achieve specific functions. Its working principle is to quickly release compressed air to produce high-frequency, high-pressure pulses, thereby achieving purposes such as cleaning, descaling, and dust removal. In bag dust collectors, pulse air compressors are used to clean the dust on filter bags, ensuring the efficient operation of the dust removal system. In addition, they are also used in large industrial vacuum cleaners to back-blow filters to keep them clean. Pulse air compressors can also be used in other situations that require cleaning and descaling, such as self-cleaning air filters in oxygen stations.

Pulse Air Compressor

Oil-free air compressor

Oil-free air compressors are devices that do not use oil during the gas compression process. They have advantages such as being clean and environmentally friendly, easy to maintain, high reliability, low noise, and strong flexibility. They are widely used in industries such as medical, food processing, electronics, pharmaceuticals, laboratories, and spray painting. The gas they output is oil-free, reducing pollution and maintenance costs, making them suitable for environments with strict air quality requirements. In addition, the simplified structure makes maintenance work more convenient, and advanced materials ensure a longer service life and high reliability. The low noise design of oil-free air compressors also makes them suitable for noise-sensitive situations.

Oil-free air compressor

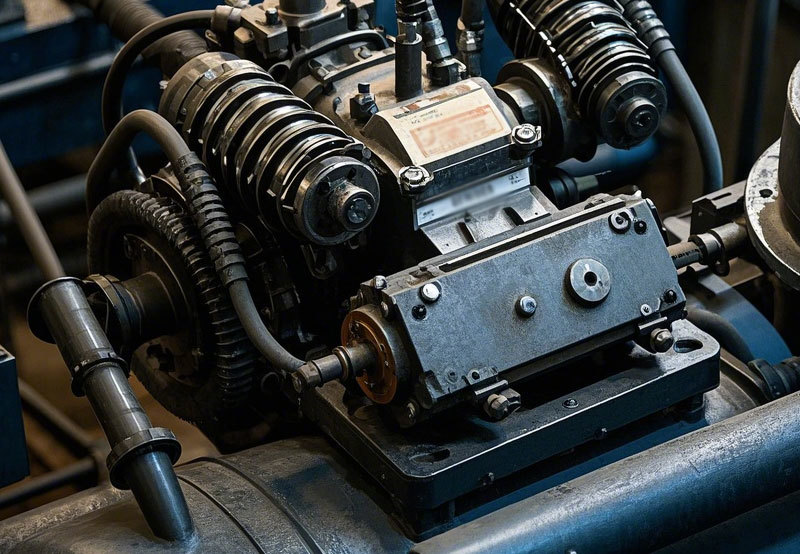

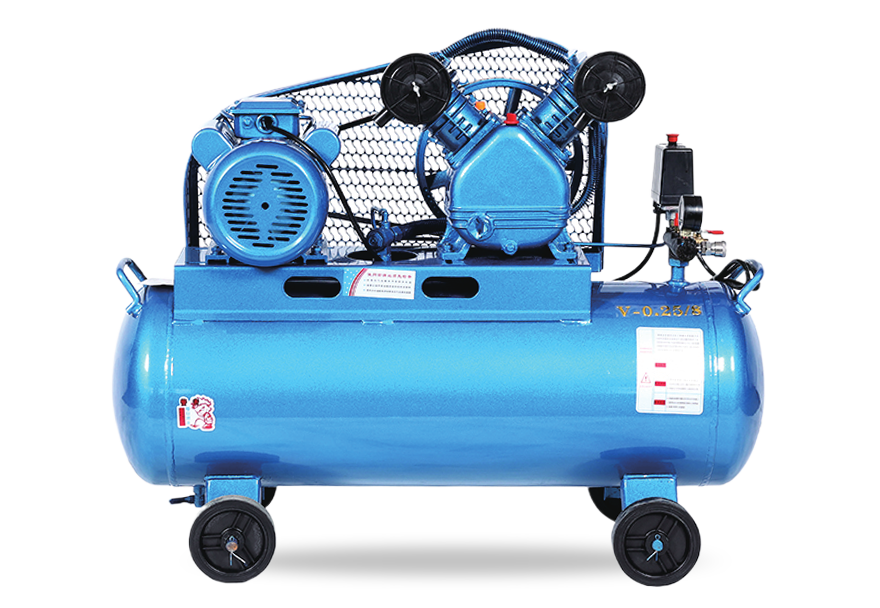

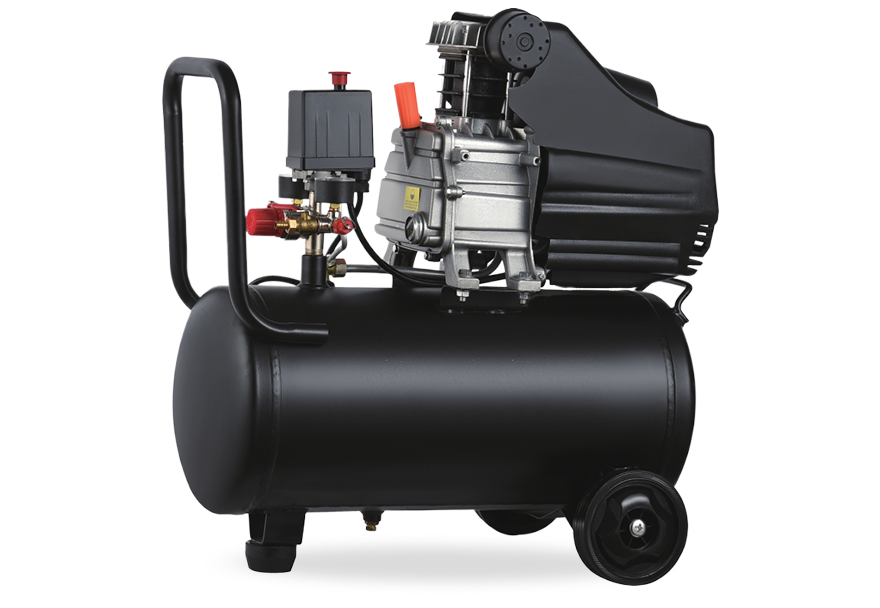

Belt air compressor

Belt-driven air compressors are a type of efficient air source equipment, widely used due to their high efficiency, lower cost, and simple structure. They enhance the working efficiency of the motor through belt transmission, which helps improve air compression effects. Compared to oil-free air compressors, belt-driven air compressors have relatively lower equipment costs and maintenance expenses, making them particularly suitable for small and medium-sized enterprises. Additionally, the design of belt-driven air compressors facilitates installation and operation, and they are highly adaptable, allowing for the selection of appropriate power and exhaust volume based on different needs. They are widely used in automotive, machining, construction, agriculture, laboratories, food industry, and metal processing fields.

Belt air compressor

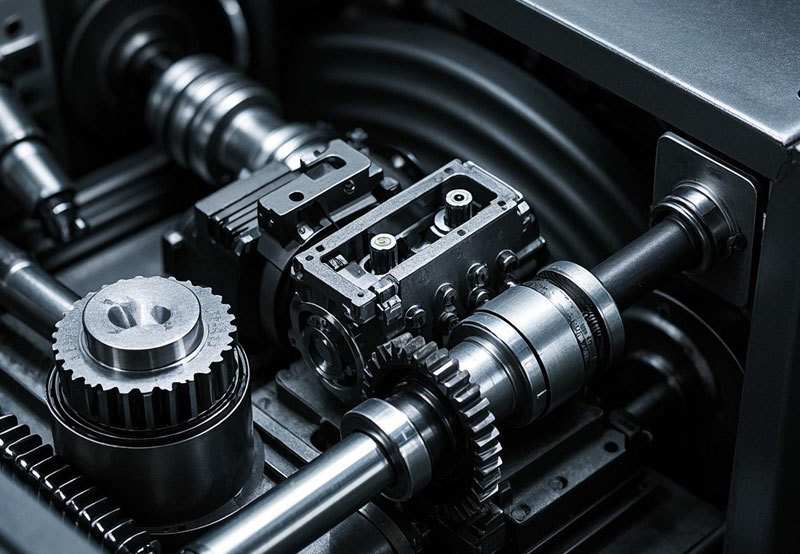

Screw air compressor

Screw-type air compressors are mechanical devices that compress air through the rotation of screws. Its core components are two intermeshing screws that compress air to a high-pressure state through a helical motion. This type of compressor has advantages such as stable operation, low noise, long lifespan, and easy maintenance, which is why it is widely used in many fields. Screw-type air compressors are widely used in manufacturing, construction, food processing, electronics, and other industries, especially suitable for scenarios that require continuous air supply. They can provide a stable air source for industrial production, support the operation of various pneumatic equipment, and can also be used for cooling, cleaning, and other auxiliary processes.

Screw air compressor

Directly Coupled Air Compressor

Directly connected compressors are a type of air compressor that transmits electric power directly to the machine head through an elastic coupling. Their transmission mechanism consumes almost no energy, resulting in very high transmission efficiency. These compressors typically use a new type of flange elastic coupling that does not require disassembly of the machine head, pipelines, and valves, thus simplifying the maintenance process. Directly connected compressors are widely used, especially in situations that require high efficiency, energy saving, and low noise. For example, in industries such as electronics and furniture, directly connected compressors are widely used due to their energy efficiency and low noise characteristics. Additionally, directly connected compressors are also used in the laser cutting industry to provide continuous, stable, and high-quality compressed gas.

Directly Coupled Air Compressor

About Us

Provide air compressor solutions for global customers

Taizhou Minyuan Machinery Co., Ltd. is a large-scale industry and trade integration enterprise specializing in the production and export of various pulse, oil-free, dental, vacuum, belt, direct connection, screw air compressors and their parts. Headquartered in Taizhou City, Zhejiang Province, South China. It has a modern factory building of 5000 square meters and more than 50 experienced workers. in addition,We have over 15 years of experience in supply chain management of OEM and ODM products. Our rich experience helps us to continuously develop new products to meet changing market needs and customer requirements. All our products are well received in the markets of Southeast Asia, Europe and South America.

Manufacturing experience

Technical Staff

Plant area

Application areas

Become the world's best ultra-quiet air compressor manufacturer, to create a comfortable and healthy working environment for users.

2024-12-18

What components of the air compressor need regular maintenance?

Regular maintenance of air compressors is crucial for ensuring their normal operation and extending their lifespan. Here are some key components that require regular maintenance:

2024-12-18

What are the applications of air compressors in industry?

Industrial Production: Air compressors are important equipment on industrial production lines, used to provide power for pneumatic tools, pneumatic machinery, and pneumatic control systems.